When a production well underperforms, the first symptom is usually subtle: a little more drawdown than last season to hit the same flow. Left alone, that “little more” becomes a permanent loss of capacity, higher energy bills, pump wear, and emergency downtime. That’s the tax of neglect. The good news: a systematic, proactive maintenance program pays for itself—often quickly—while extending asset life and protecting service reliability.

Below is the economic case, grounded in industry guidance and field data, with an operator‑first playbook you can put to work now.

What “neglect” looks like in groundwater wells

Operators monitor specific capacity (SC)—flow divided by drawdown (gpm/ft)—because it’s the most practical indicator of well condition. As screens, gravel packs, and formation pores accumulate scale (e.g., CaCO₃, Fe/Mn oxides), biofilms (iron bacteria), fines/sediment, and corrosion products, head losses rise and SC falls. A widely used rule of thumb is to initiate rehabilitation when SC declines ~25% from baseline; well levels should be logged monthly and SC tested at least semi‑annually. (Water Replenishment District)

Two consequences make delay expensive:

- Irreversibility risk. If SC is “allowed to drop too far, it may not be able to be reversed and the useful life of the well may come to an end.” That’s not alarmist language—that’s a technical bulletin written for public agencies. (Water Replenishment District)

- Escalating costs. Extension guidance notes the same pattern: waiting can “significantly increase costs and in some cases make rehabilitation impossible.” (Penn State Extension)

The hidden costs of a declining well

1) Energy penalty—paid every hour the pump runs

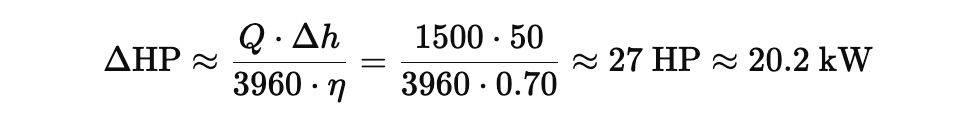

As drawdown increases, your pump must lift water farther. Pump power rises approximately with flow × head / (3960 × pump efficiency [decimal value]), so each additional foot of drawdown is a permanent energy tax for as long as you operate at that flow. (Engineering ToolBox)

For context, EPA estimates energy can be up to 40% of a drinking water system’s operating cost, and water/wastewater systems consume about 2% of U.S. electricity. Cutting avoidable head losses matters. (US EPA)

2) Reliability and firm capacity risk

Ten States–style criteria used by many regulators require groundwater source capacity to meet design maximum day demand with the largest well out of service. If neglect forces you to take a big producer offline unexpectedly, you may no longer meet “firm capacity,” with consequences ranging from water purchase premiums to customer restrictions. (See, e.g., New Mexico Environment Department)

3) Pump and screen damage from sand or corrosion

Corroded or enlarged screen slots can pass sand into the well; sand then abrades pump internals and shortens equipment life—an expensive failure cascade. (Penn State Extension)

4) Schedule and permitting delays

Even a well‑planned rehab can require NPDES/waste discharge permits. Expect 30–45 days just for permitting and disposal plans—another reason to schedule proactively on your timeline, not after a failure. (Water Replenishment District)

The big-ticket comparison most boards understand

Replacement is expensive. In a 2017 water master plan appendix prepared for the City of Modesto (CA), the estimated construction cost for a new 1,500–2,000 gpm well (400–500 ft) was about $2.3 million, and $3.5 million including soft costs. (Modesto Government)

Rehabilitation is variable—but typically far less. Public‑sector tech guidance shows rehab components often range in the thousands to tens of thousands per event depending on scope (pulling pumps, test pumping, mechanical/chemical treatments, disposal). Some larger municipal rehabs can run into the hundreds of thousands or more, but that’s still materially below replacement and often restores most of the lost capacity. (Water Replenishment District)

Routine maintenance costs are modest. Real-world bid tabs for municipal well inspection/maintenance frequently land in the low five figures per well per year—pennies on the dollar relative to rehabilitation or replacement.

A simple cost–benefit you can take to finance

Let’s quantify one common scenario for a municipal production well:

- Well: 1,500 gpm

- Observed decline (neglect case): SC down 50%, requiring +50 ft of drawdown to hold 1,500 gpm

- Pump efficiency: 70%

- Electricity: $0.12/kWh (illustrative average)

Energy penalty from extra head:

At continuous operation, that’s ~176,800 kWh/yr or ~$21,200/yr in avoidable energy spend—every year—just to overcome preventable well losses. (Formula reference.) (Engineering ToolBox)

Now evaluate an intervention:

- One-time comprehensive rehab: $200k (illustrative mid-range; actuals vary)

- Proactive maintenance plan: $10-25k/yr (inspection, monitoring, minor cleaning; aligns with typical bid magnitudes)

- Expected benefit: SC recovery that removes ~50 ft of avoidable head (energy savings ≈ $21k/yr), plus deferral of replacement by 5 years (time‑value benefit of deferring a $2.3M capital outlay)

Five‑year NPV (5% discount):

- Benefits:

- Energy savings ≈ $92k NPV

- Replacement deferral ≈ $498k NPV (the value of not spending $2.3M today)

- Total ≈ $590k NPV

- Costs:

- Rehab now $200k

- Maintenance $25k/yr ≈ $111k NPV

- Total ≈ $311k NPV

Net ≈ $190k NPV, an ≈61% ROI over five years—before considering avoided emergency rentals, overtime, water purchase, or reputational/regulatory costs from outages. (EPA reminds us energy can be up to 40% of O&M, so the energy line item alone is material.) (US EPA)

Takeaway: Even conservative assumptions favor proactive maintenance. As declines deepen, rehab success rates fall, energy penalties grow, and the math gets more favorable still. (Water Replenishment District)

“Can a well ever not recover?” — Yes.

When plugging extends beyond the screen into the gravel pack and near‑well formation, the best you may achieve is a partial recovery. Industry guidance is direct: rehabilitate at ~25% SC loss; delays can make recovery impossible. If you wait until SC is halved—or the well starts pumping sand—you may be buying a new well sooner than planned. (Water Replenishment District)

What a proactive well program looks like (operator’s playbook)

1) Establish a baseline.

Compile drilling logs, initial step‑drawdown and 24‑hour test results, screen intervals, pump curves, and initial SC. This becomes your control for trend analysis. (Water Replenishment District)

2) Monitor on a schedule.

- Monthly: Static and pumping water levels, flow, kW, and sand content (if feasible).

- Semi‑annual: Specific capacity test at stable operating conditions; trend SC against baseline.

- Event-driven: Downhole video when trends worsen or sand appears. (Water Replenishment District)

3) Set triggers and act early.

- SC decline ≥ 15–25%: Plan rehab window and scope.

- Sudden sand or turbidity spikes: Inspect screens; address corrosion or screen slot enlargement before pump damage escalates. (Penn State Extension)

4) Use the right tools for the right fouling mechanism.

- Mechanical: brushing, swabbing, airlift/surge, jetting, acoustic agitation.

- Chemical: acids for mineral scale; oxidants/biocides for biofilms; CO₂ or blended chemistries as appropriate. (Often combined for depth of penetration and debris removal.) (Water Replenishment District)

5) Capture the energy win.

Pair rehabilitation with a quick pump optimization check—verify you’re operating near best efficiency (BEP) at the restored head, and update VFD setpoints or pump staging accordingly. (EPA’s energy guidance provides tools and benchmarks.) (US EPA)

6) Schedule smart.

Secure discharge/disposal permits 30–45 days ahead; book vendors in shoulder seasons (pre‑summer demand). (Water Replenishment District)

7) Design for maintainability.

When building or equipping new wells, include access ports for chemical introduction, spinner/video logging, and zone sampling so you can perform more work without pulling the pump. (Water Replenishment District)

8) Align with standards and asset management.

Reference AWWA A100 (Water Wells), C654 (Disinfection of Wells), and your state’s firm capacity expectations. Fold well assets into your asset management plan (inventory, condition, criticality, O&M, CIP, financing) so you can defend preventive budgets with data. (American Water Works Association)

“We have limited budget—how do we start?”

If you can do one thing this quarter: start consistent SC tracking (a simple spreadsheet is enough) and set the 25% trigger. The minute you have trend lines, you have a business case.

Lean program (minimal cost):

- Monthly levels + flows + kW, semi‑annual SC; sand checks; annual downhole video for priority wells.

- Pre‑book shoulder‑season time with a qualified well service firm for brushing/surging and targeted chemical treatments. (Water Replenishment District)

Standard program:

- Everything in Lean, plus integrated energy monitoring (verify kW per MG trend), routine bacteriological/chemistry checks to diagnose fouling type, and targeted rehab at the 15–25% loss point. (US EPA)

Comprehensive program:

- Add predictive analytics (SCADA tags for drawdown/flow/kW), periodic spinner logs, and condition‑based pump servicing. Bake the program into your asset management and CIP, and communicate the avoided‑cost ROI to finance. (US EPA)

Talking points for your board or CFO

- We’re protecting firm capacity. Proactive work keeps us inside design day criteria even with one well down. (New Mexico Environment Department)

- We’re lowering total cost of ownership. Maintenance is a fraction of rehabilitation, and rehabilitation is a fraction of replacement; acting early maximizes recovery and minimizes energy waste. (Water Replenishment District)

- We’re reducing controllable O&M (energy). Avoidable head losses cost real money; EPA pegs energy at up to 40% of water O&M. (US EPA)

- We’re following standards. AWWA standards and asset‑management best practices support this approach. (American Water Works Association)

Bottom line

Neglect is expensive—in dollars, in risk, and in credibility. Proactive well maintenance—anchored in monthly measurements, semi‑annual SC trending, early intervention at ~25% loss, and smart scheduling—pays back through lower energy bills, longer well life, fewer emergencies, and a defensible plan for ratepayers and regulators.